Product Description

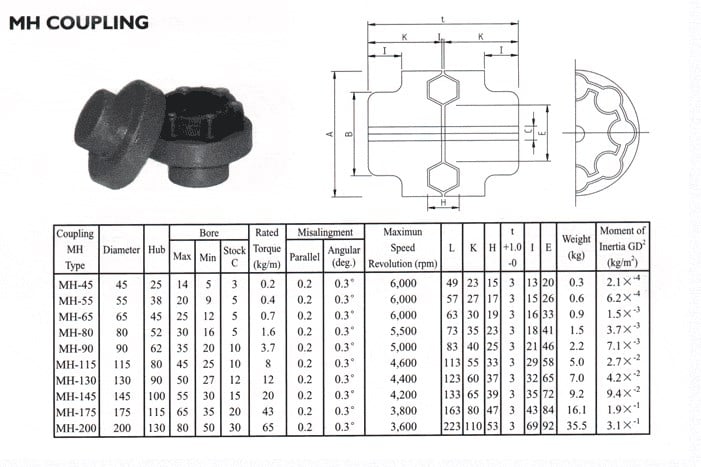

MH Rubber Flex Coupling Spider – Rubber Bush Coupling Manufacturer

Specification:

| Name | MH Coupling Rubber Elastic spider ring |

| Material | Silicone, EPDM, NR, NBR, FKM, SBR, HNBR, IIR, CR FFKM etc silicon,fluorine,NBR,FPM,EPDM,SILCONE ACM,HNBR |

| Size | According to the drawing or sample |

| Color | According to your requirement (Panton color card) |

| Application | Parts are used on vehicles, printing machines, food processing machines, textile machines, electronic machines, etc. |

| Inspection instruments | Excellent chemical and physical property, excellent oil- resistance, high temperature stability, etc. |

| Package | Inner plastic bag/outside carton/wooden pallets/ or any other special package as per customer’s requirements |

| Final inspection | We’ll make a final QC 100% inspection to make sure a good quality before delivery |

MH coupling consists of 2 flanges and flexible ring able to compensate all types of shaft misalignments.The flexible rings are made of synthetic rubber with steel cores reinforced for improve reliability and maximum operating speed of the coupling. The damping characteristic of the rubber anable to absorb and dampen torsional vibrations, operate effectively in temperature range of -40 to +100 °C. The rubber also resists to oil, dirt, grease, moisture, CHINAMFG and many chemical solvents

| Coupling Type | Serial No | |

| HYPERFLEX MH | MH45 | NBR Rubber Spider |

| HYPERFLEX MH | MH55 | NBR Rubber Spider |

| HYPERFLEX MH | MH65 | NBR Rubber Spider |

| HYPERFLEX MH | MH80 | NBR Rubber Spider |

| HYPERFLEX MH | MH90 | NBR Rubber Spider |

| HYPERFLEX MH | MH115 | NBR Rubber Spider |

| HYPERFLEX MH | MH130 | NBR Rubber Spider |

| HYPERFLEX MH | MH145 | NBR Rubber Spider |

| HYPERFLEX MH | MH175 | NBR Rubber Spider |

| HYPERFLEX MH | MH200 | NBR Rubber Spider |

| HYPERFLEX MH | MH230 | NBR Rubber Spider |

Application

Other related coupling splider

FAQ

Q: Are you manufacturer or trading company?

A: We are manufacturer, engineer had rich experience over 20 years.

Q: How to get the quickest quotation?

A: Sending drawing, material, quantity and other rrequirements by email.

Q: How to get quotation without drawing?

A: Possible send sample, pictures or detail descriptions of products to us, we will return you drawing for confirm.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help? A. Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Q: My custom products have already been developed on CAD. Can you use the drawings?

A. Yes! DWG, DXF, IGES, Solidworks and Rhino files can all be used to generate quotes, models and mould tools – this can save time and money in producing your parts.

Q: Can I test my idea/product before committing to mould tool manufacture?

A. Yes, we can use CAD drawings to make models for design and functional evaluations.

Q: What type of plastic/rubber material is best for my design/product?

A. Materials selection depends on the application of your design and the environment in which it will function. We will be happy to discuss the alternatives and suggest the best material.

Q: How to get sample?

A: Free sample is available for your quality evaluation, but you should pay the freight. Regarding customize products, sample and mould order will go first before mass production.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Usage: | Industrial |

|---|---|

| Material: | Rubber, NBR, PU |

| OEM/ODM: | Welcomed |

| Color: | Black or Custom |

| Serial: | Hyperflex Mh |

| Hardness: | Sha93 |

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can flexible couplings be used in both horizontal and vertical shaft arrangements?

Yes, flexible couplings can be used in both horizontal and vertical shaft arrangements. The design of flexible couplings allows them to accommodate misalignment and compensate for angular, parallel, and axial displacements between the shafts, making them suitable for various shaft orientations.

Horizontal Shaft Arrangements:

In horizontal shaft arrangements, where the shafts are parallel to the ground or horizontal plane, flexible couplings are commonly used to connect two rotating shafts. These couplings help transmit torque from one shaft to another while accommodating any misalignment that may occur during operation. Horizontal shaft arrangements are common in applications such as pumps, compressors, conveyors, and industrial machinery.

Vertical Shaft Arrangements:

In vertical shaft arrangements, where the shafts are perpendicular to the ground or vertical plane, flexible couplings are also applicable. Vertical shafts often require couplings that can handle the additional weight and forces resulting from gravity. Flexible couplings designed for vertical applications can support the weight of the rotating equipment while allowing for some axial movement to accommodate thermal expansion or other displacements. Vertical shaft arrangements are commonly found in applications such as pumps, gearboxes, turbines, and some marine propulsion systems.

Considerations for Vertical Shaft Arrangements:

When using flexible couplings in vertical shaft arrangements, there are a few additional considerations to keep in mind:

- Thrust Load: Vertical shafts can generate thrust loads, especially in upward or downward direction. The flexible coupling should be selected based on its capacity to handle both radial and axial loads to accommodate these forces.

- Lubrication: Some vertical couplings may require additional lubrication to ensure smooth operation and reduce wear, particularly if they are exposed to high axial loads or extended vertical shafts.

- Support and Bearing: Proper support and bearing arrangements for the vertical shaft are essential to prevent excessive shaft deflection and ensure the flexible coupling functions correctly.

Overall, flexible couplings are versatile and adaptable to various shaft orientations, providing efficient power transmission and misalignment compensation. Whether in horizontal or vertical arrangements, using the appropriate flexible coupling design and considering the specific application requirements will help ensure reliable and efficient operation.

Can flexible couplings be used in applications with varying operating temperatures?

Yes, flexible couplings can be used in applications with varying operating temperatures. The suitability of a flexible coupling for a specific temperature range depends on its design and the materials used in its construction. Different types of flexible couplings are available to handle a wide range of temperature conditions, making them versatile for use in various industries and environments.

High-Temperature Applications:

For applications with high operating temperatures, such as those found in certain industrial processes, exhaust systems, or high-temperature machinery, flexible couplings made from materials with excellent heat resistance are used. These materials may include stainless steel alloys, heat-treated steels, or specialized high-temperature elastomers. High-temperature flexible couplings are designed to maintain their mechanical properties, including flexibility and torque transmission capabilities, even at elevated temperatures.

Low-Temperature Applications:

Conversely, for applications in extremely cold environments or cryogenic processes, flexible couplings constructed from materials with low-temperature resistance are employed. These couplings are designed to remain flexible and functional at very low temperatures without becoming brittle or losing their ability to handle misalignment. Some low-temperature couplings may use special polymers or elastomers with excellent cold-temperature performance.

Temperature Range Considerations:

When selecting a flexible coupling for applications with varying operating temperatures, it is essential to consider the specific temperature range in which the coupling will operate. Some flexible couplings have a wider temperature range, allowing them to function effectively in both high and low-temperature environments. However, in extreme temperature conditions, specialized couplings may be necessary to ensure reliable performance and prevent premature failure.

Manufacturer Guidelines:

Manufacturers of flexible couplings provide guidelines and specifications regarding the temperature range of their products. It is crucial to consult the manufacturer’s documentation to ensure that the chosen coupling is suitable for the intended operating temperature of the application. Using a coupling beyond its recommended temperature range can lead to performance issues, reduced efficiency, or even failure.

Applications:

Flexible couplings with varying temperature resistance find use in numerous industries, including aerospace, automotive, manufacturing, power generation, and more. Whether in high-temperature exhaust systems, low-temperature cryogenic processes, or regular industrial applications with temperature fluctuations, flexible couplings play a vital role in providing reliable power transmission and misalignment compensation.

In summary, flexible couplings can be effectively used in applications with varying operating temperatures, provided that the coupling’s design and material properties align with the specific temperature requirements of the application.

What is a flexible coupling and how does it work?

A flexible coupling is a mechanical device used to connect two shafts while allowing for relative movement between them. It is designed to transmit torque from one shaft to another while compensating for misalignment, vibration, and shock. Flexible couplings are essential components in various rotating machinery and systems, as they help protect the connected equipment and enhance overall performance.

Types of Flexible Couplings:

There are several types of flexible couplings, each with its unique design and characteristics. Some common types include:

- Jaw Couplings: Jaw couplings feature elastomer spiders that fit between two hubs. They can accommodate angular and parallel misalignment while dampening vibrations.

- Disc Couplings: Disc couplings use thin metallic discs to connect the shafts. They are highly flexible and provide excellent misalignment compensation.

- Gear Couplings: Gear couplings use gear teeth to transmit torque. They offer high torque capacity and can handle moderate misalignment.

- Beam Couplings: Beam couplings use a single piece of flexible material, such as a metal beam, to transmit torque while compensating for misalignment.

- Bellows Couplings: Bellows couplings use a bellows-like structure to allow for axial, angular, and parallel misalignment compensation.

- Oldham Couplings: Oldham couplings use three discs, with the middle one having a perpendicular slot to allow for misalignment compensation.

How a Flexible Coupling Works:

The operation of a flexible coupling depends on its specific design, but the general principles are similar. Let’s take the example of a jaw coupling to explain how a flexible coupling works:

- Two shafts are connected to the coupling hubs on either side, with an elastomer spider placed between them.

- When torque is applied to one shaft, it causes the spider to compress and deform slightly, transmitting the torque to the other shaft.

- In case of misalignment between the shafts, the elastomer spider flexes and compensates for the misalignment, ensuring smooth torque transmission without imposing excessive loads on the shafts or connected equipment.

- The elastomer spider also acts as a damping element, absorbing vibrations and shocks during operation, which reduces wear on the equipment and enhances system stability.

Overall, the flexibility and ability to compensate for misalignment are the key features that allow a flexible coupling to function effectively. The choice of a specific flexible coupling type depends on the application’s requirements, such as torque capacity, misalignment compensation, and environmental conditions.

editor by CX 2024-03-06