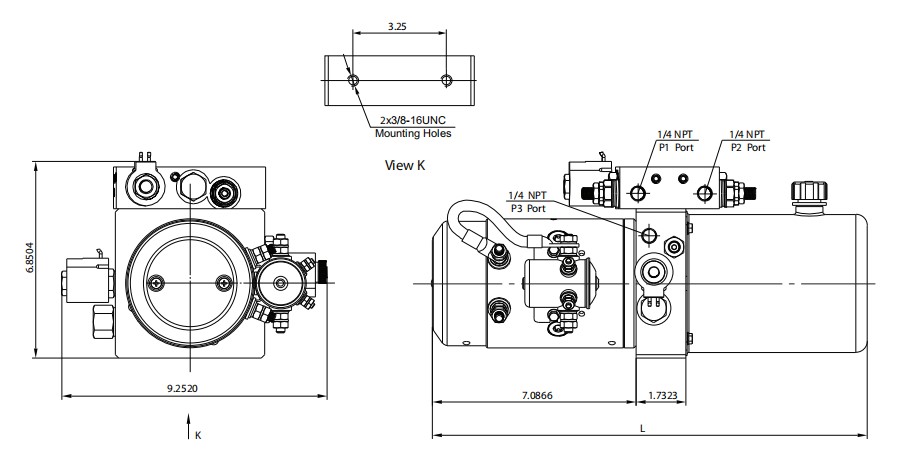

Common Description

Consisting of a pressure balanced gear pump, DC motor, multi-functional manifold, valves, tank, ect., this energy unit is made to operate material handling tools. The lowering movement is achived through the solenoid valve with all the lowering pace managed by an adjustable needle valve. The left and right functions are outfitted with a dual pilot operated test valve and cross-over relief valves.

Remark: Please talk to our revenue engineer for the different pump displacement, motor power or tank capacity.

Unique Notes

one. This power unit is of S3 duty cycle, i.e.,non-continuous operation,thirty seconds on and 270 seconds off.

two. Clean every one of the hydraulic parts concerned in advance of installation of the electrical power unit.

three. Viscosity of your hydraulic oil shoud be 15~46 cst, which should also be clean and  no cost of impurities.N46 hydraulic oil is advisable.

no cost of impurities.N46 hydraulic oil is advisable.

four. This power unit must be mounted horizontal.

five. Check the oil degree while in the tank following the initial commence in the energy unit.

6. Oil changing is required immediately after the initial 100 operation hours, afterwards when each and every 3000 hours.