The 14 sizes of conventional roller chains are available ranging from 25 to 240 which include those in conformity with ANSI (American Nationwide Regular Institute), and ISO (Worldwide Organization for Standardization).

The chains not only meet the demands for that minimal tensile strength prescribed by ANSI and ISO, nevertheless they also provide the top rated class quality in the world such as a large fatigue power

Suitable uses

?General use for driving and lifting tools.

Examples

?Driving transfer units and also other equipment. For multilevel parking.

Selection of chains

For variety of a chain, see the tables of “Max. Horsepower Ratings” for conventional roller chains and “Designing of Chain Transmission”. Nevertheless, only to get a unique situation of lower velocity and significantly less shock, “Low-speed selection” process also can be referred to.

Typical roller chains as much as five strands can be found. The common process for connecting pins and plates is rivet form (RP).

The cotter style (CP) is  obtainable for standard chains and HK chains of 80 or greater.

obtainable for standard chains and HK chains of 80 or greater.

Sprockets

The regular roller chains may be engaged with conventional sprockets with the corresponding nominal numbers. For sprockets, refer to the table of “Dimensions” for every dimension of chain.

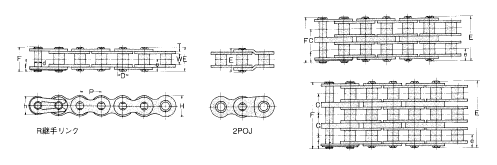

Connecting back links and offset links

For connecting back links and offset back links, refer on the table of “Dimensions” for every size of chain.

The connecting hyperlinks are normally R or C connecting links by which the pins are clearance-fitted with the connecting plate. Considering that clearance-fitted back links are inferior to the base chain in Max. allowable stress as from the situation of one-pitch offset links (OJ), “Low-speed selection” cannot be referred to. Since the Max. kilowatt ratings are RIVETLESS DROP FORGED CHAIN BAR LOOP CHAIN decided contemplating the strength of connecting hyperlinks and OJ, the clearance-fitted connecting backlinks and OJ is usually made use of in the event the chains are chosen in accordance to the “General selection”. Whenever a higher Max. allowable stress is required for your connecting hyperlink, utilize the interference-fitted connecting hyperlink (H connecting link) of a HI-PWR-S chain, and in the case of offset links, use 2POJ.